India contributes nearly 20% of the world’s chip design engineers, making it a powerhouse in semiconductor design. However, despite this talent edge, very few Indian-made chip products have emerged—a gap noted by industry experts and policymakers

Why India Holds 20% of Global Chip Design Talent

- A report by Bastion Research states that about one in five chip design engineers globally are based in India—largely servicing major firms like Qualcomm, Intel, Nvidia, Broadcom, and MediaTek via R&D centers in Bengaluru, Hyderabad, and Noida.

- Deloitte confirms this, placing India as a critical hub for chip design efforts like logic implementation, testing, optimization, and firmware development.

- According to the ITIF report, India boasts approximately 125,000 semiconductor design engineers and contributes significantly to global VLSI designs and integration.

Why Few Made-in-India Chip Products Exist

1. Design vs. Manufacturing Gap

India’s strength remains in the design domain. It has limited fabrication, packaging, and full-stack semiconductor capabilities. As a result, most chip manufacturing continues to occur abroad.

2. Global Value Chain Role

The country’s position in the semiconductor value chain is largely secondary—Indian engineers execute design and simulation, while strategic architecture and product decisions occur overseas.

3. Infrastructure & Investment Needs

Building a full semiconductor ecosystem—covering chip design, fabrication, testing, and packaging—requires massive investments, infrastructure support, and strong policy incentives.

Insights from Industry Leadership

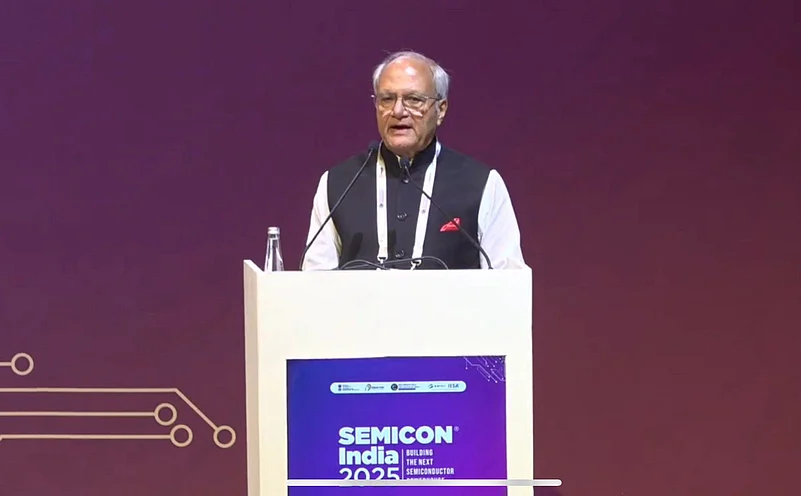

Ajai Chowdhry, Co-Founder of HCL Infosystems and Chairman at EPIC Foundation, underlined the disconnect:

“India holds nearly 20% of the world’s design capability, but most of this capacity today services global companies. We rarely leverage this strength to design and build our own products.”

Chowdhry emphasized that India must move beyond design and towards systems-level innovation—building hundreds of chip and product companies to foster self-reliance and value addition.

Charting India’s Semiconductor Future

| Aspect | Status |

|---|---|

| Design Engineering | Strong, with ~20% of global talent based in India |

| Made-in-India Chips | Limited—few indigenous products exist, mostly academic or niche projects |

| Manufacturing Capacity | Nascent—limited fabs, packaging, or full-stack ecosystem |

| Industry Direction | Shifting toward product-led growth; startup & policy support expanding |

Progress Ahead

Efforts are underway to close the gap:

- IIT (ISM) Dhanbad showcased a homegrown analog memristor chip—APEEC1—demonstrating Indian academic progress.

- The HCL-Foxconn JV was cleared for chip production in UP, aiming to produce 20,000 wafers monthly by 2027

- L&T Semiconductor Technologies, a fabless startup, plans to build a $10B fab by 2027, backed by high fabs subsidies.TechRadar

Conclusion

India stands as a global leader in chip design talent, but this strength has yet to translate equitably into made-in-India semiconductor products and manufacturing capabilities. Bridging this gap will require integrated investments, domestic innovation, and a strategic ecosystem approach.